Asiga Pro 4k

The Asiga PRO 4K is the world’s most advanced DLP imaging technology to achieve the largest print envelope in our range in a small footprint.

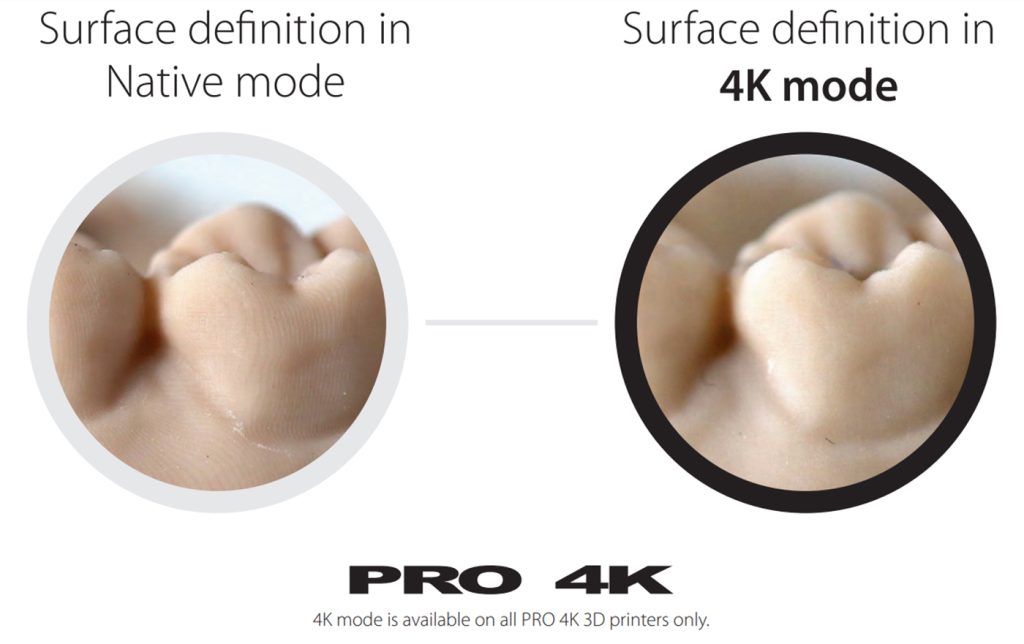

4K Super Fast Print Mode

The PRO 4K incorporates pixel shifting technology to increase part accuracy and surface definition without affecting printing time.4K mode is a standard feature on every PRO 4K. Native pixel mode is also available for scientific applications requiring deterministic pixel behavior.

SPS™ Smart-Positioning-System Technology

Asiga's unique SPS™ process guarantees every layer is formed accurately. Accurate layer formation is the key to achieving consistently accurate results in any production environment.

« SPS™ - How it Works

The Latest 4K DLP Imaging Technology

Coupled with custom engineered optics for precision pixel placement.

Industry Proven Performance

Precision, reliability and speed for the most demanding production applications.

Process

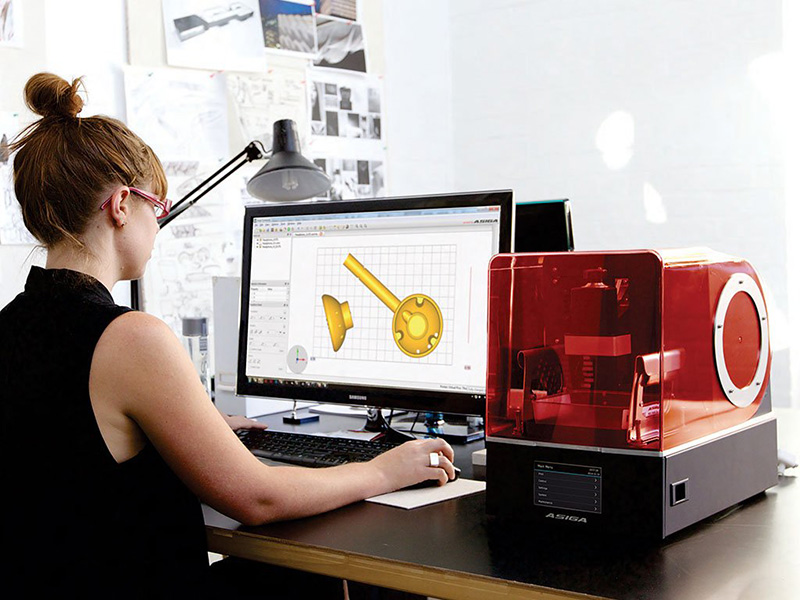

DESIGN AND PREPARE

Design models on CAD Software and export it as an STL file and import it in Asiga Composer Slicing software to prepare jobs for Asiga 3D Printers.

After preparing the job submit it to Asiga 3D Printer and start the job by navigating from the touchscreen display from the 3D printer.

POST PROCESS AND USE

After the job is finished post process the parts by cleaning it, removing supports and post curing, then use as per designed application.

Technical Specification

Asiga Pro 4k

Build volume:

X:176mm, Y:99mm, Z: 200mm

Layer height:

- Internal radiometer: An internal radiometer actively monitors LED intensity during every build ensuring the correct light exposure is delivered for each layer.

- High power UV 385nm LED: Why 385nm UV LEDs? 3Dmaterials cure faster at deeper UV wavelengths (385nm) reducing XY scattering and over-cure. The result is consistent accuracy, production reliability and the ability to process water-clear materials.

- Small pixel and accurate pixel placement : Pixel size and pixel placement are crucial for reproducing digital data accurately. For dentistry, we recommend pixel sizes between 60 – 80 µm depending on application.

- Precise material curing: Our Open Material System allows for any suitable material to be printed. Material curing parameters fore ach material are generated by Asiga ensuring materials are cured accurately for repeatable results.

Compatible materials

Model Resin

Asiga PlasGRAY

Asiga PlasCLEAR