Form 3B+

An Advanced Desktop 3D Printer Designed for Healthcare

Rapidly print patient-specific parts at the point of care and bring innovative R&D and commercial production in-house with the Form 3B+, an advanced 3D printer for healthcare professionals and medical device engineers.

The Form 3B+ is compatible with our entire SLA materials library, including biocompatible, sterilizable materials.

From First Print to Standard of Care

With a compact footprint, affordable price point, and access to a multitude of high-performance materials, use the Form 3B+ for your first print and add more as you scale.

Precision 3D Prints

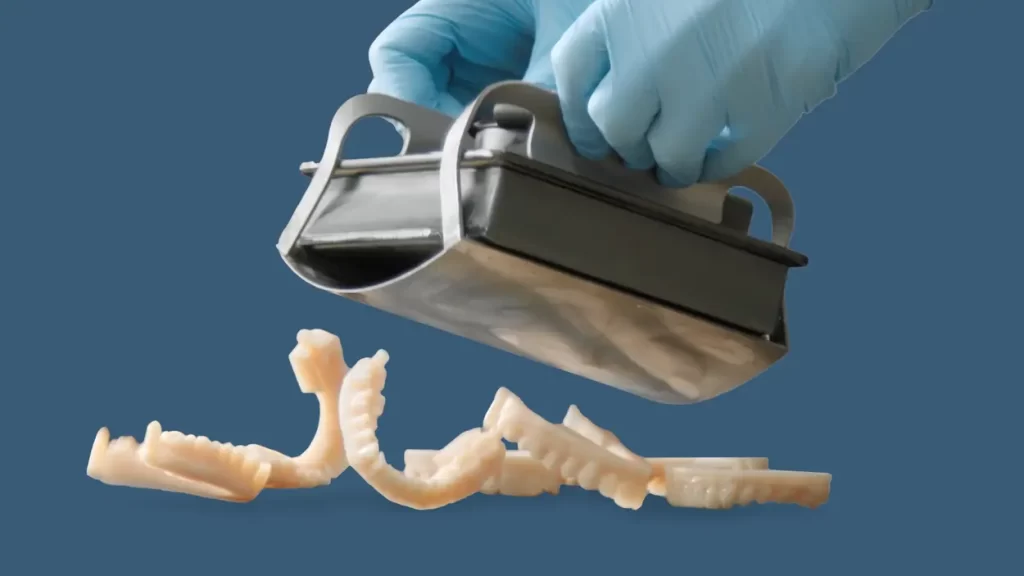

The Form 3B+ is large enough to print several surgical instruments and medical devices. With a compact footprint, nimbly scale capacity as demand increases. Over 70M medical devices were printed on Formlabs SLA printers in 2020 alone.

On-Demand Printing

From time-sensitive point of care printing to groundbreaking medical devices, work faster and have full control with a versatile, accessible, and scalable 3D printer on site.

Validated Workflows

The Form 3B+ has been validated in FDA-cleared workflows. It is also compatible with a wide range of biocompatible, sterilizable materials manufactured in our FDA-registered, ISO 13485 certified facility.

Meet the Form 3B+

Form 3B+ is ideal for:

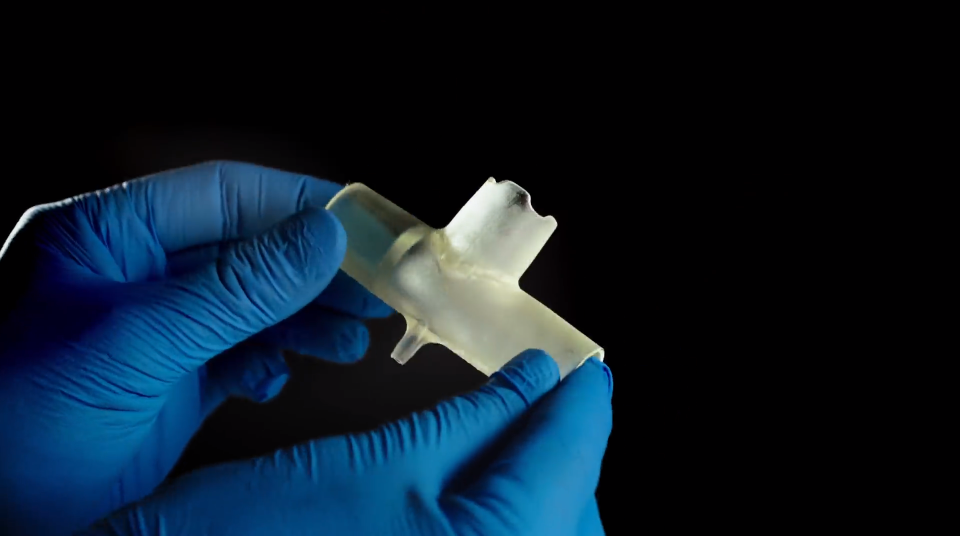

Small and medium parts requiring biocompatibility and sterilization compatibility

Patient-specific anatomical models and surgical instruments

Surgical planning models for diagnostic use in FDA-cleared workflows

Medical device prototypes, jigs, fixtures, molds, and end-use parts

Visual aids for diagnosis and education

Research and development with advanced materials

Always on call

The Form 3B+ works around the clock with minimal supervision. With finely tuned settings that optimize print times, the Form 3B+ helps you meet critical deadlines, even for time-sensitive parts and models for trauma surgery.

Intuitive and efficient

Seamlessly integrate the Form 3B+ into your existing clinical workflows. With automatic resin dispensing, simple print preparation software, and intuitive accessories like Build Platform 2 with patented Quick Release Technology, the Form 3B+ is designed for efficiency.

Materials for a Wide Array of Applications

Access a library of 40+ materials compatible with the Form 3B+. Our technology has been validated in multiple FDA-cleared workflows and we develop and manufacture our own biocompatible materials in an ISO 13485 certified, FDA-registered facility. Parts can be sterilized using steam, e-beam, gamma, or EtO.

Materials for a Wide Array of Applications

Access a library of 40+ materials compatible with the Form 3B+. Our technology has been validated in multiple FDA-cleared workflows and we develop and manufacture our own biocompatible materials in an ISO 13485 certified, FDA-registered facility. Parts can be sterilized using steam, e-beam, gamma, or EtO.

Open System to Unlock Innovation in Healthcare

Formlabs Open Platform empowers healthcare professionals to drive groundbreaking advancements. Customizable print settings and the ability to print with any 405nm photopolymer resin on Form 3B+ allow users to unleash unlimited possibilities for medical R&D.

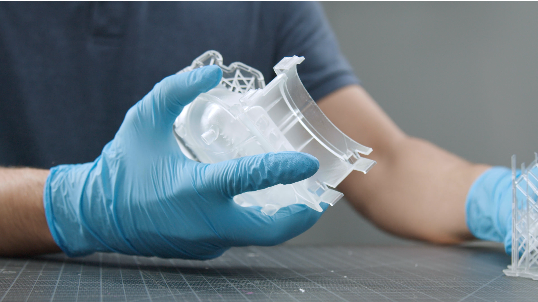

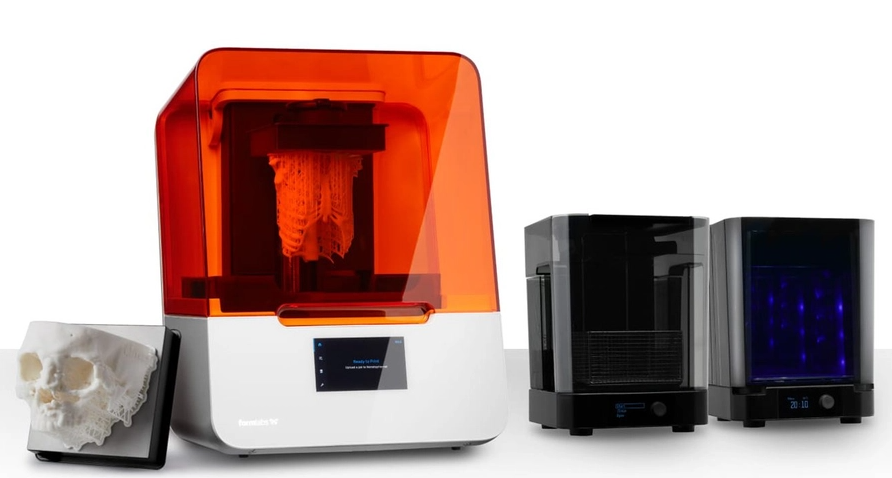

The Form 3B+ Workflow

Get more done and work more efficiently with an end-to-end 3D printing workflow. From printing to post-processing, each step of the process was designed with efficiency in mind.

Design

3D PRINT OR REVERSE ENGINEER

Remove Part

Remove Supports

Cure

Transfer the parts to the Form Cure to maximize material properties and ensure peak dimensional accuracy.

Quick Release Technology

Build Platform 2 with patented Quick Release Technology quickly and easily releases parts from the build platform without tools.

Enhanced Light Touch Supports

Decrease post-processing time with our enhanced light touch supports structures that break off easier and cleaner than ever before.

Achieve a Flawless Finish

Streamline your workflow and enhance surface finish with Formlabs’ curated set of Finishing Tools.

Part of the Formlabs Ecosystem

Formlabs is known for designing end-to-end additive workflows you’ll be excited to use. The Form 3B+ is trusted by clinical innovators as part of surgical workflows.

Automated Wash and Cure

Deliver strong, ready-to-use parts with less time and effort. Form Wash and Form Cure streamline and automate rinsing and post-curing of prints.

Support When You Need It

Get helpful, human service when you need it from a Formlabs expert, with plans that scale with your business.

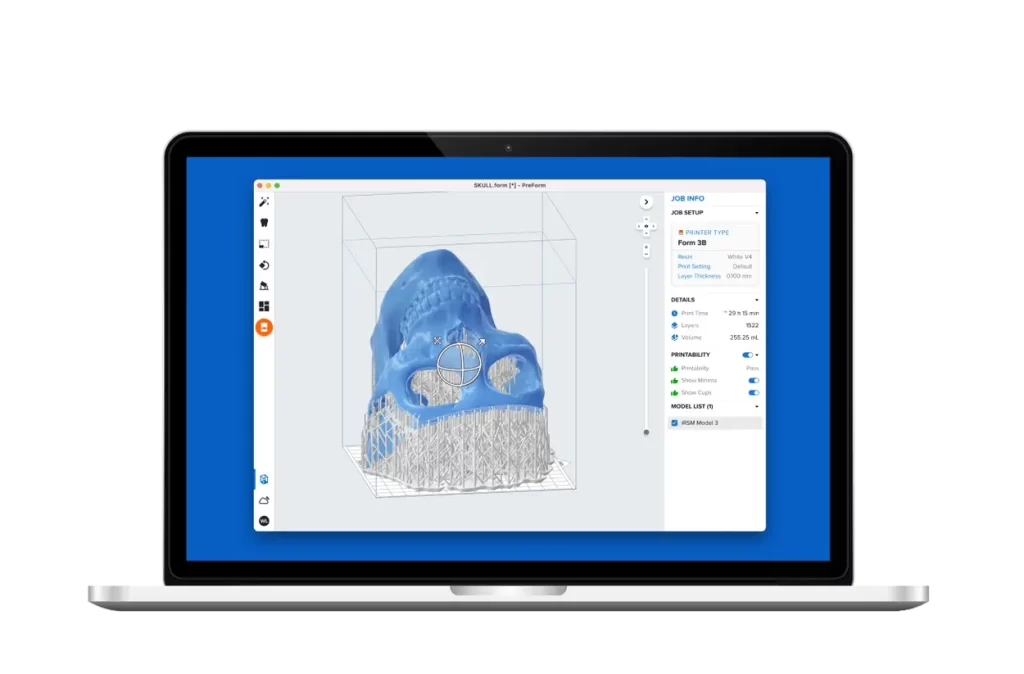

Industry-Leading Software

Plan and manage your print queue in PreForm and manage printers and teams through your online Dashboard.

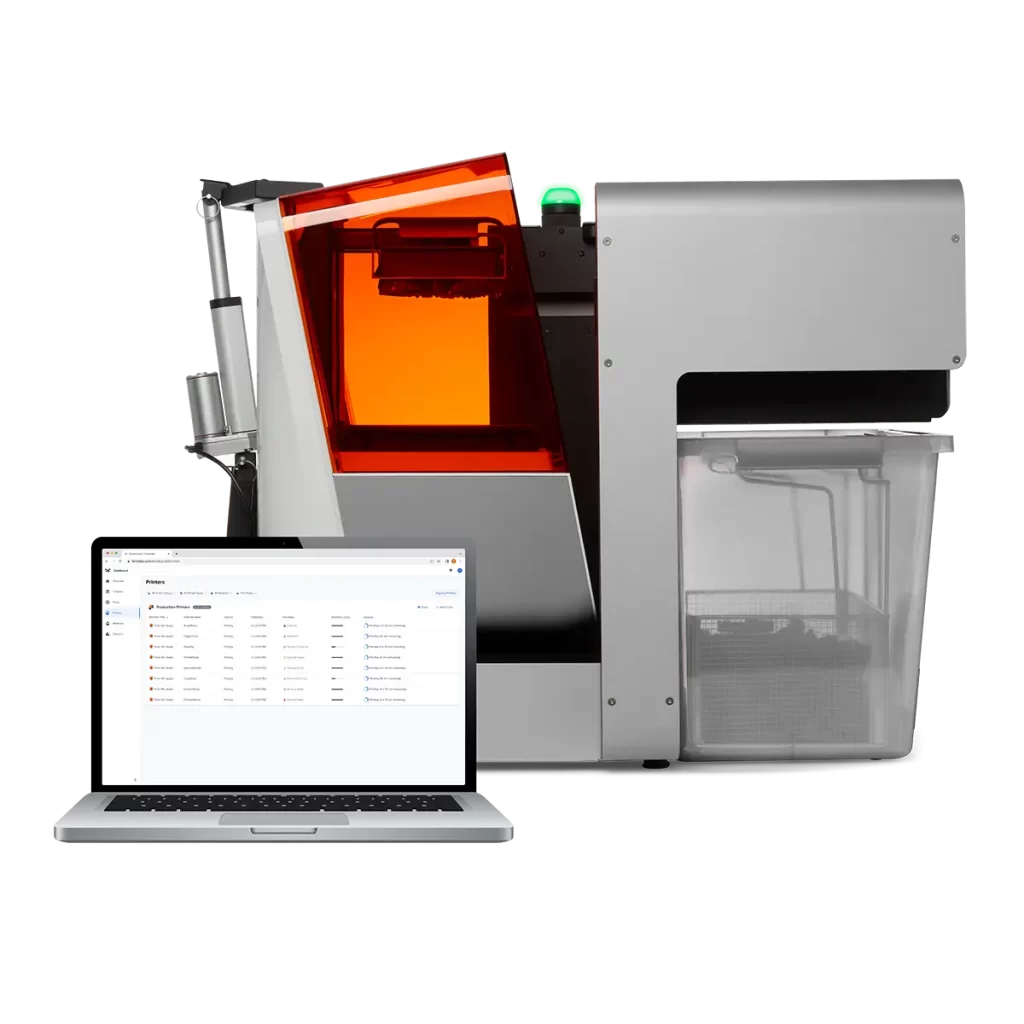

Maximize Your 3D Printer Fleet’s Throughput with 24/7 Production

Reach new levels of productivity with a fully automated fleet of Form 3B+ 3D printers that you can operate from anywhere. Skyrocket your ability to produce high-quality, affordable parts with 24/7 back-to-back production with the Formlabs Automation Ecosystem: Form Auto, Fleet Control, and Resin Pumping System.

Join Thousands of Your Peers and Adopt Validated, Accessible, and Versatile Medical 3D Printing Today

Meet critical deadlines in-house without prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of medical experts.

Printing Technology: Low Force Stereolithography (LFS)

Laser: Light Processing Unit (LPU), 250 mW405 nm

Build Volume: 145 x 145 x 185 mm

Z-Layer Resolution: 25 – 300 microns

XY Resolution: 25 microns

UI: 5.5-inch touchscreen

Connectivity: WiFi, Ethernet, USB

Build Platform Leveling: Automatic

Materials: Formlabs resin cartridges