Manufacturing Solutions for Plastic Materials

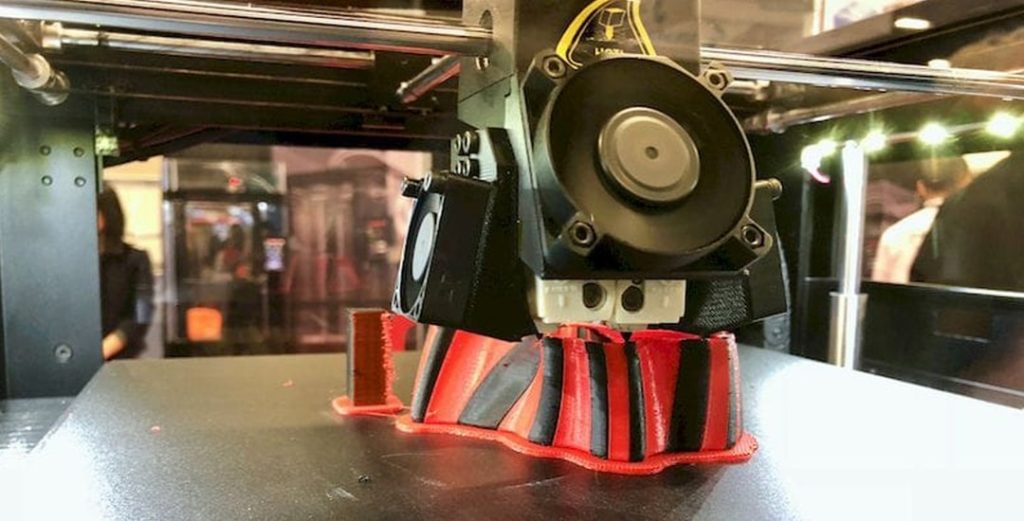

FDM (Fused Deposition Modeling)

Fused Deposition Modeling is the most basic explanation of additive manufacturing. The process of FDM is the extrusion of different kind of polymer materials to create an object layer by layer from a 3D file such as toys, figurines, arts & crafts, scale models, and prototype.

Choose from a wide ranging materials like PLA, ABS, Nylon, ASA, PC, PETG, and High Temp materials.

Raise3D PVA Pure White

Raise3D Premium PETG Black

Raise3D Premium PC White

Raise3D Premium PC Transparent

Raise3D Premium PC Black

Raise3D Premium ABS White

Raise3D Premium ABS Grey

Raise3D Premium ABS Black

Raise3D Premium PLA Yellow

Raise3D Premium PLA White

Raise3D Premium PLA Orange

Raise3D Premium PLA Blue

Raise3D Premium PLA Black

Raise3D Premium PLA Red

3DXMAX ASA White

3DXMAX ASA Flat Dark Earth

3DXMAX ASA Natural

3DXMAX ASA Dark Grey

3DXMAX ASA Black

3DXMAX ASA Army Green

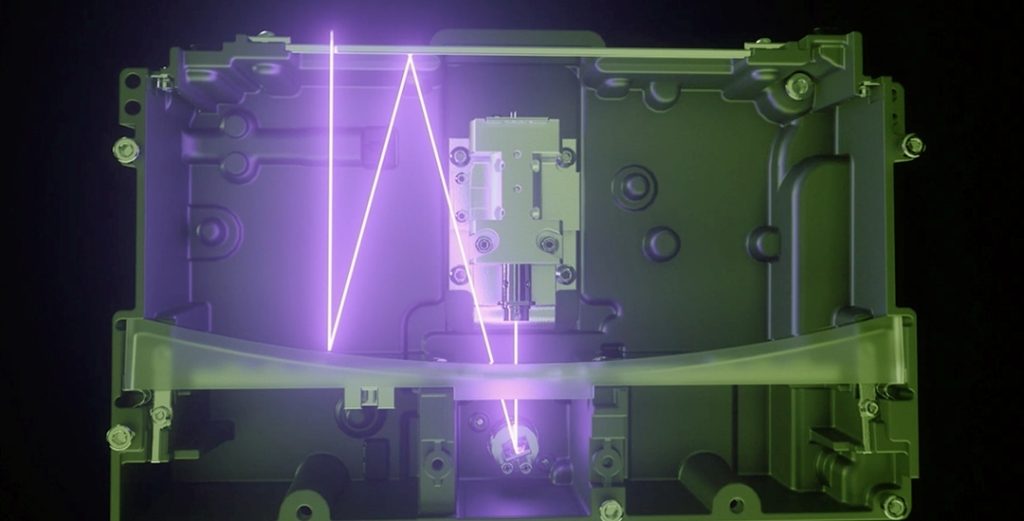

SLA (Stereolithography)

Stereolithography (SLA) is the first additive manufacturing to be ever developed. It is a form of 3D printing technology that uses parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform giving the smoothest surface finish available in the market.

SLA technology is a wide ranging solution for standard, engineering, castable wax, and biocompatible 3D printing.

Standard Grey Resin

Standard Black Resin

Standard White Resin

Standard Clear Resin

Draft Resin

Tough 2000 Resin

Durable Resin

Tough 1500 Resin

Flexible 80A Resin

Elastic 50A Resin

Rigid Resin

Grey Pro Resin

Castable Wax Resin

Model Resin

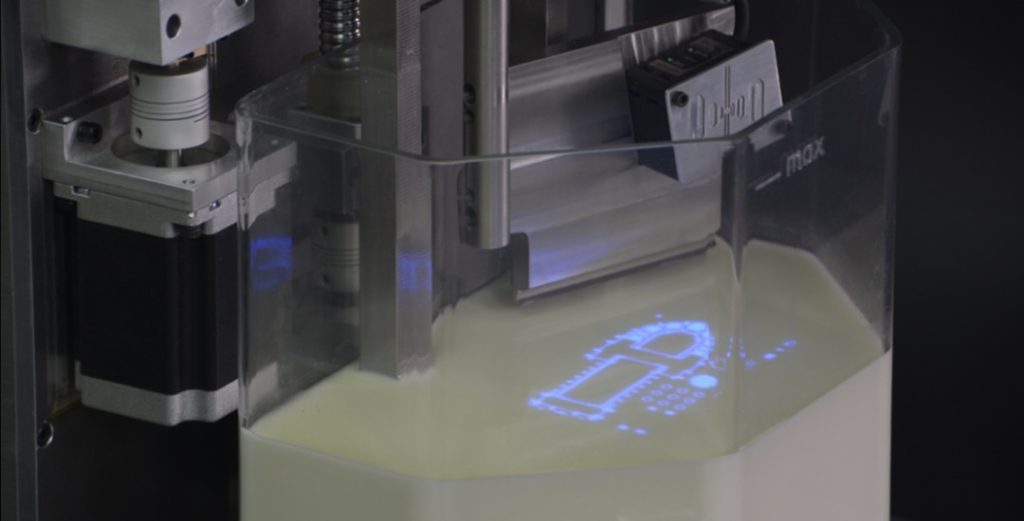

DLP (Digital Light Processing)

DLP technology is perfect choice for digital manufacturing for Industry-wide compatibility from Jewellery, Dental, and Audiology production.

Digital Light Processing is quite similar with SLA technology but it uses a projector light instead of a single laser and it produce faster output than stereolithography.

Asiga PlasGRAY

Asiga PlasCLEAR

SLS

An industrial 3D printing process that delivers accurate prototypes and functional production parts as faster than other 3D printers in the market. Selective Laser Sintering (SLS) can produce complex geometries without support and faster than other 3D printing technology in the market today.

SLS uses a laser to sinter small particles of polymer powder. Polyamide 12 (PA 12) is the most widely used material for SLS technology and continuing to develop more materials such as PA12 glass-fiber.

Nylon 12 Powder

Nylon 12 GF Powder