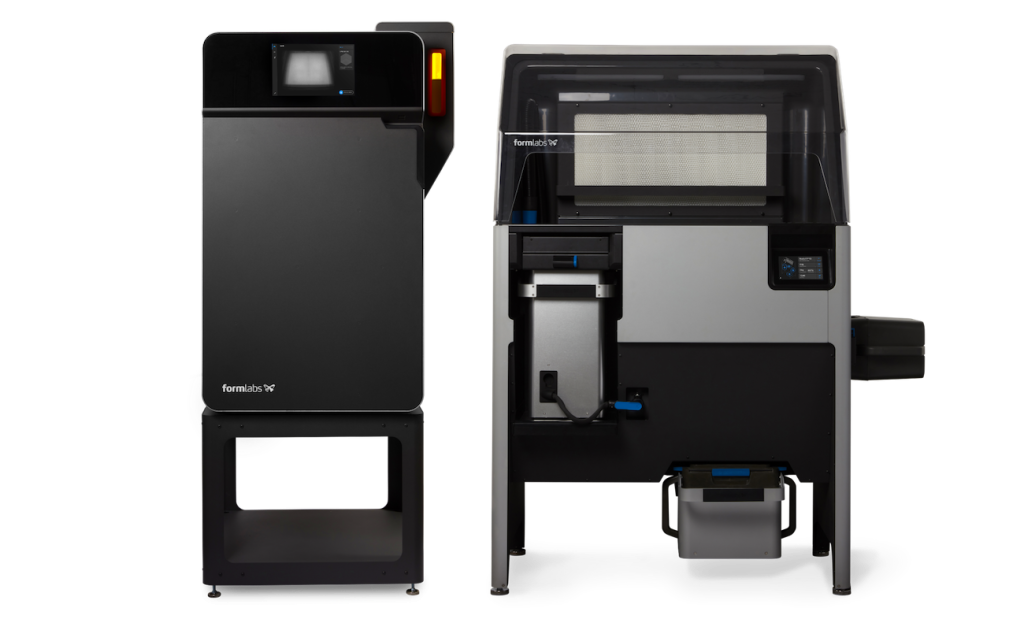

Fuse 1+ 30W

A new wave of independent manufacturing and prototyping starts now with the Fuse 1. Bring production-ready nylon 3D printing onto your benchtop with an affordable, compact selective laser sintering (SLS) platform.

Designed for non-stop throughput.

Add a second removable build chamber, compatible with the Fuse 1 and Fuse Sift, to enable continuous printing and reduce downtime. Industry leading cooldown times allow you to start a print 1–2 hours after your previous print has finished.

A Convenient, Intuitive Workflow

A new wave of independent manufacturing and prototyping starts now with the Fuse 1. Bring production-ready nylon 3D printing onto your benchtop with an affordable, compact selective laser sintering (SLS) platform.

Nylon 12 Powder

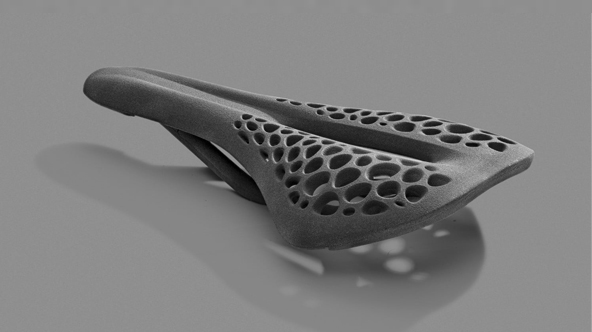

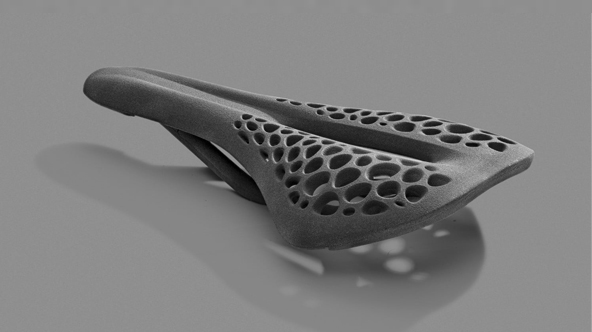

A Material That Does It All

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability. Our Nylon 12 Powder is specifically developed for use on the Fuse 1.

Nylon 12 available now. Nylon 11 is coming soon. A flexible TPU and other materials in development.

Process

Selective laser sintering (SLS) uses a laser to precisely fuse nylon powder into lightweight, robust parts.

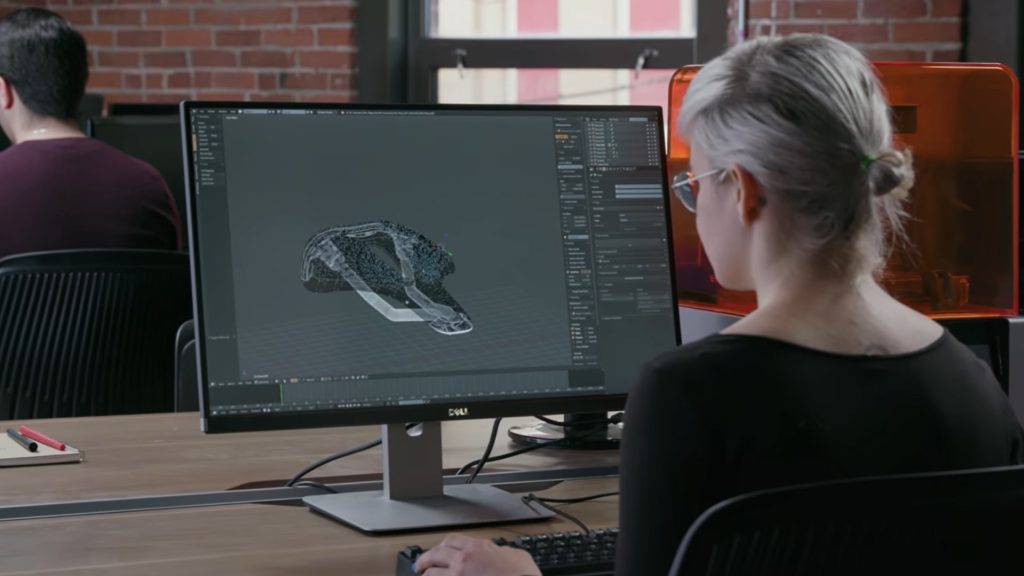

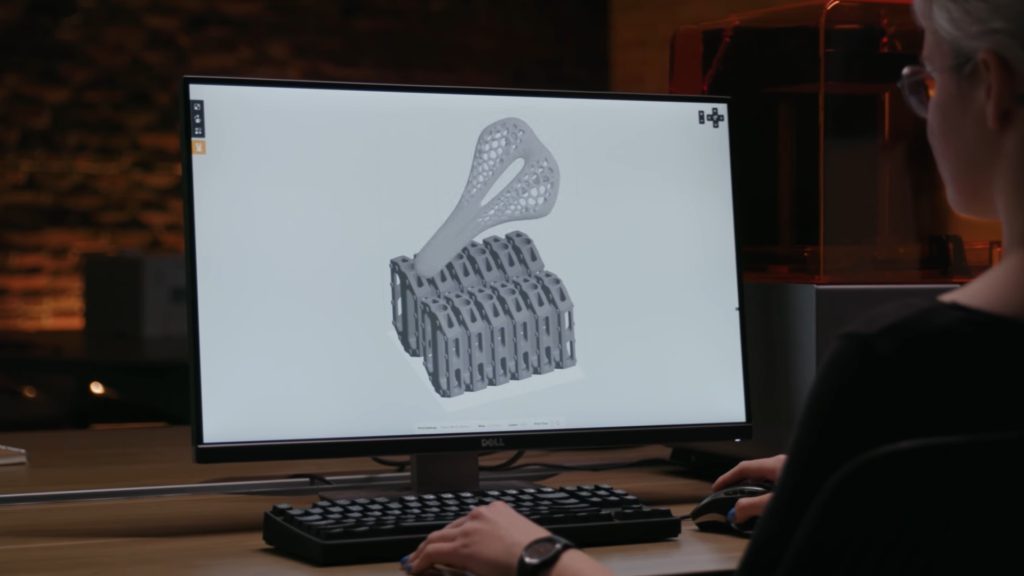

Design

Prepare

Technical Specification

Raise3D Pro3

Build volume:

Layer height:

Technology | Selective Laser Sintering

|

Build Volume (W × D × H)

| 16.5 x 16.5 x 30 cm |

Layer Thickness

| 110 microns

|

Laser Type

| Ytterbium Fiber 10W

|

Laser Spot Size (FWHM)

| 200 microns |

Material Refresh Rate

| 30% – 50%

|

Build Chamber

| Modular, compatible with Fuse 1 and Fuse Sift

|