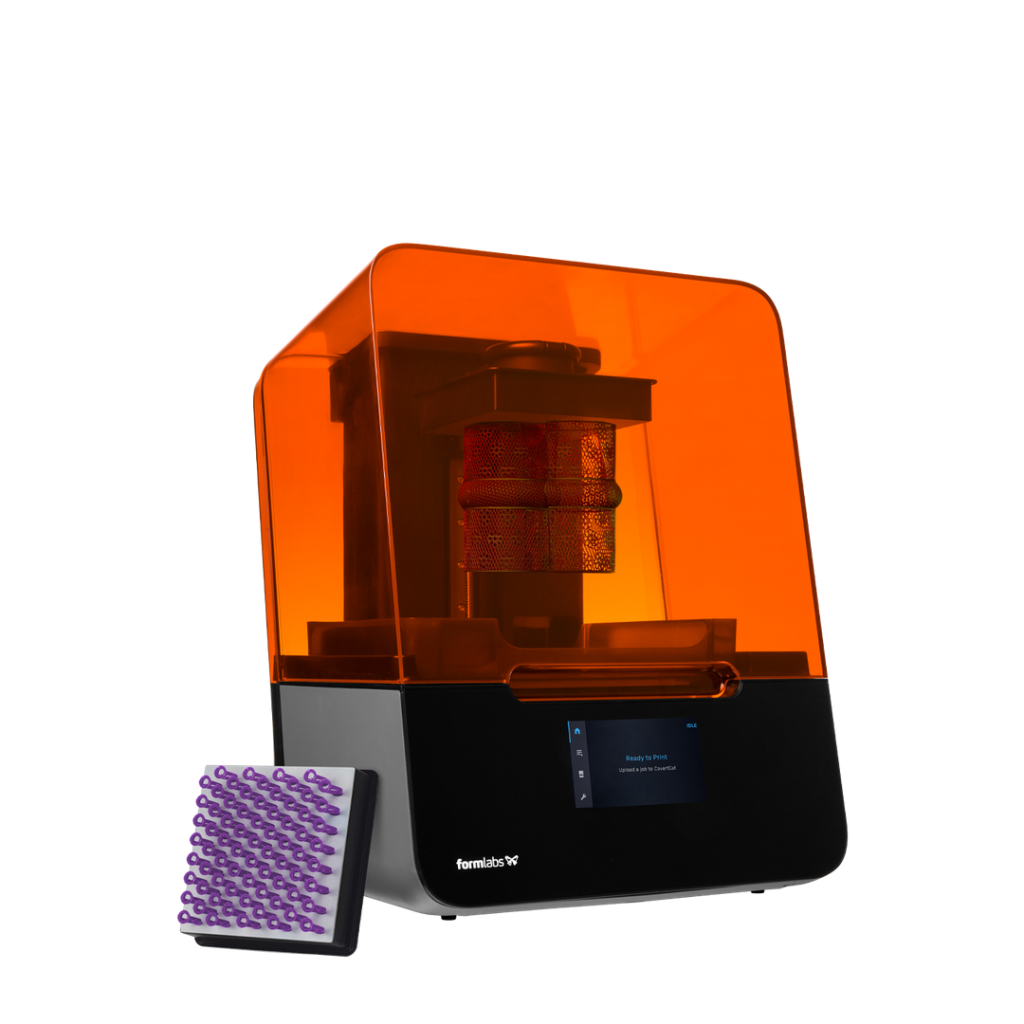

Form 3+

The Form 3’s seamless print process, high accuracy, and smooth surface finish allow you to move directly from design to production. Whether you are 3D printing try on pieces for customers, ready to cast custom jewelry, or masters for reusable jewelry molds, Formlabs offers a material up to the task.

Rubber Molds For Production Casting

Make master patterns for rubber molding with 3D printing for faster iteration and lower costs. Use the masters to create molds that produce waxes in quantity for investment casting. Standard Resins are perfect for cold molding (RTV) and High Temp Resin withstands the heat of vulcanizing natural rubber.

A Complete 3D Printing Solution for Jewelry

The Form 3’s seamless print process, high accuracy, and smooth surface finish allow you to move directly from design to production. Whether you are 3D printing try on pieces for customers, ready to cast custom jewelry, or masters for reusable jewelry molds, Formlabs offers a material up to the task.

Fittings and Consultations

Take advantage of the Form 3 to create “fitting pieces” to provide a consultative experience which builds excitement and delights your clients. SLA 3D prints are sturdier and more cost-effective than wax originals and can be reproduced or adjusted with a few clicks.

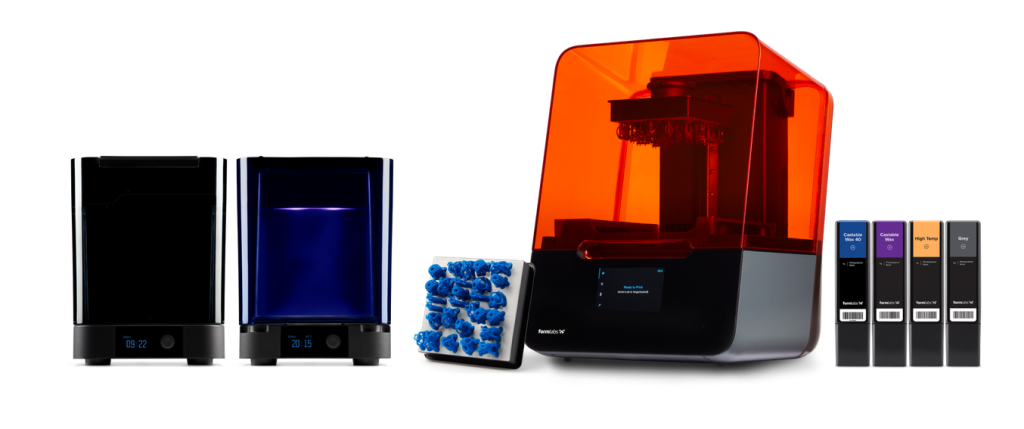

Process

The Form 3 is a part of a 3D printing ecosystem that’s easy to learn and use and requires little intervention or maintenance.

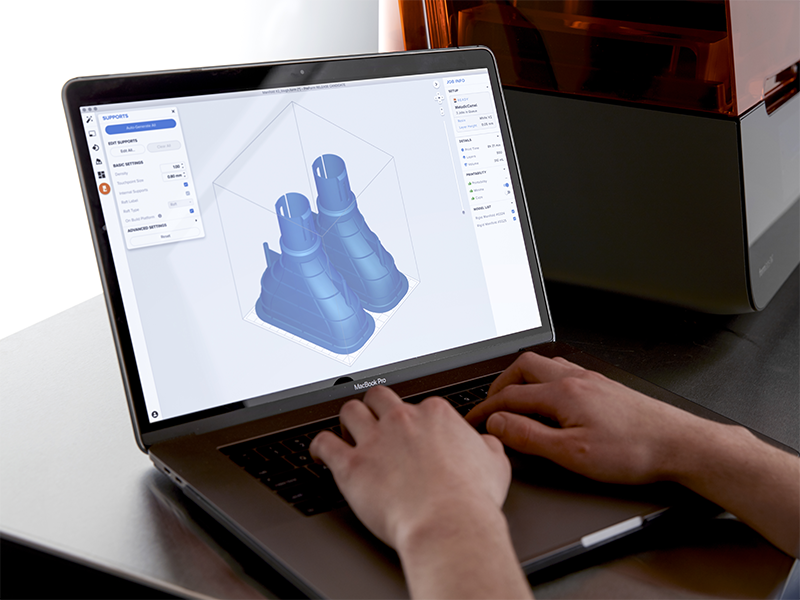

Prepare

Import your STL or OBJ file of your design and Prepare it using Formlabs PreForm software.

Send prepared prints over WiFi, and manage your printer with ease with the printer’s intuitive touchscreen interface.

Post-Process

Easily tear away light-touch supports after printing, then transfer parts to Form Wash and Form Cure for simplified rinsing and post-curing.

Technical Specification

Raise3D Pro3

Build volume:

Layer height:

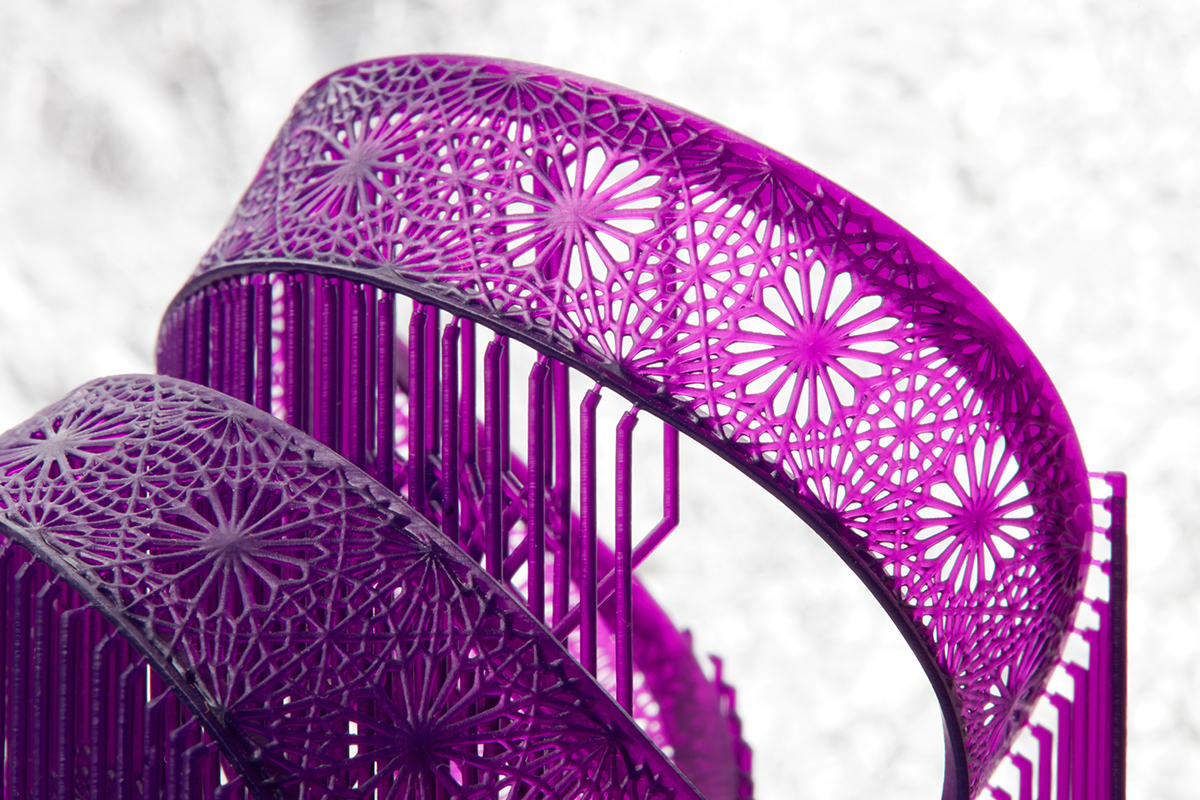

- Crisp, clean features:

The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot.

- Consistent printing:

A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform.

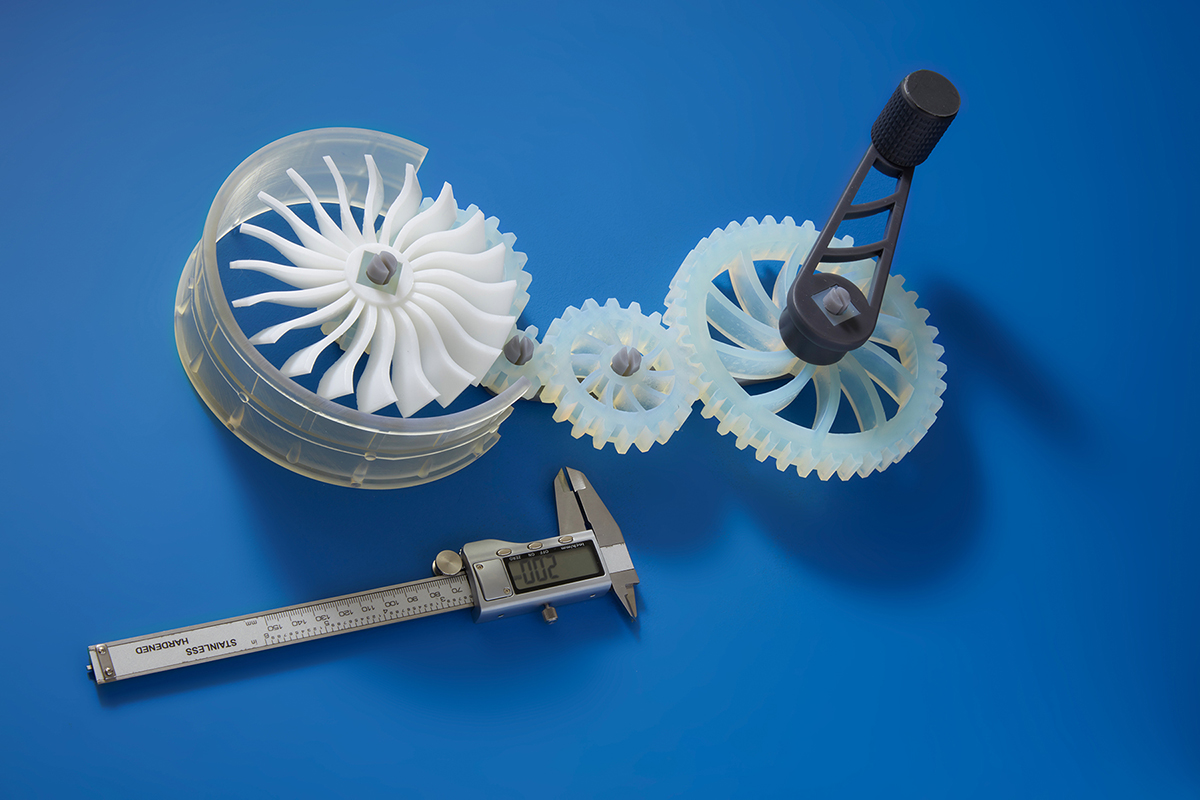

- Improved part clarity:

With LFS technology’s improved layer registration and surface finish, translucent materials print clearer than ever, right off the printer.

- Closed-loop calibration:

Optical sensors continuously correct for scale and power, and can even detect dust.

- Hassle-free materials management:

Switch between materials in seconds with a simple cartridge system.

- User-replaceable components:

The Light Processing Unit, rollers, and optics window can be replaced in-house, reducing the need for replacement printer shipments.

- Industrial quality for all:

The Form 3 offers industrial capabilities at a fraction of the price of traditional industrial machines.

- Get started now:

Formlabs 3D printers are ready to plug and print right out of the box, no specialized training required.

- Avoid delays:

Bringing production in-house with the Form 3 provides the fast turnaround time and flexibility you need to scale.

Compatible materials

Standard Grey Resin

Rigid Resin

Durable Resin